This week we investigate a new touchable hologram that allows you to grab the image and rotate it. We look into a smart airplane window that can provide geographic information as you fly over unknown countries wondering where you are. We discover how a quasicrystal can improve the strength of a 3D printed metal. Finally we examine a new method for generating electricity from rainwater.

Touchable Holograms

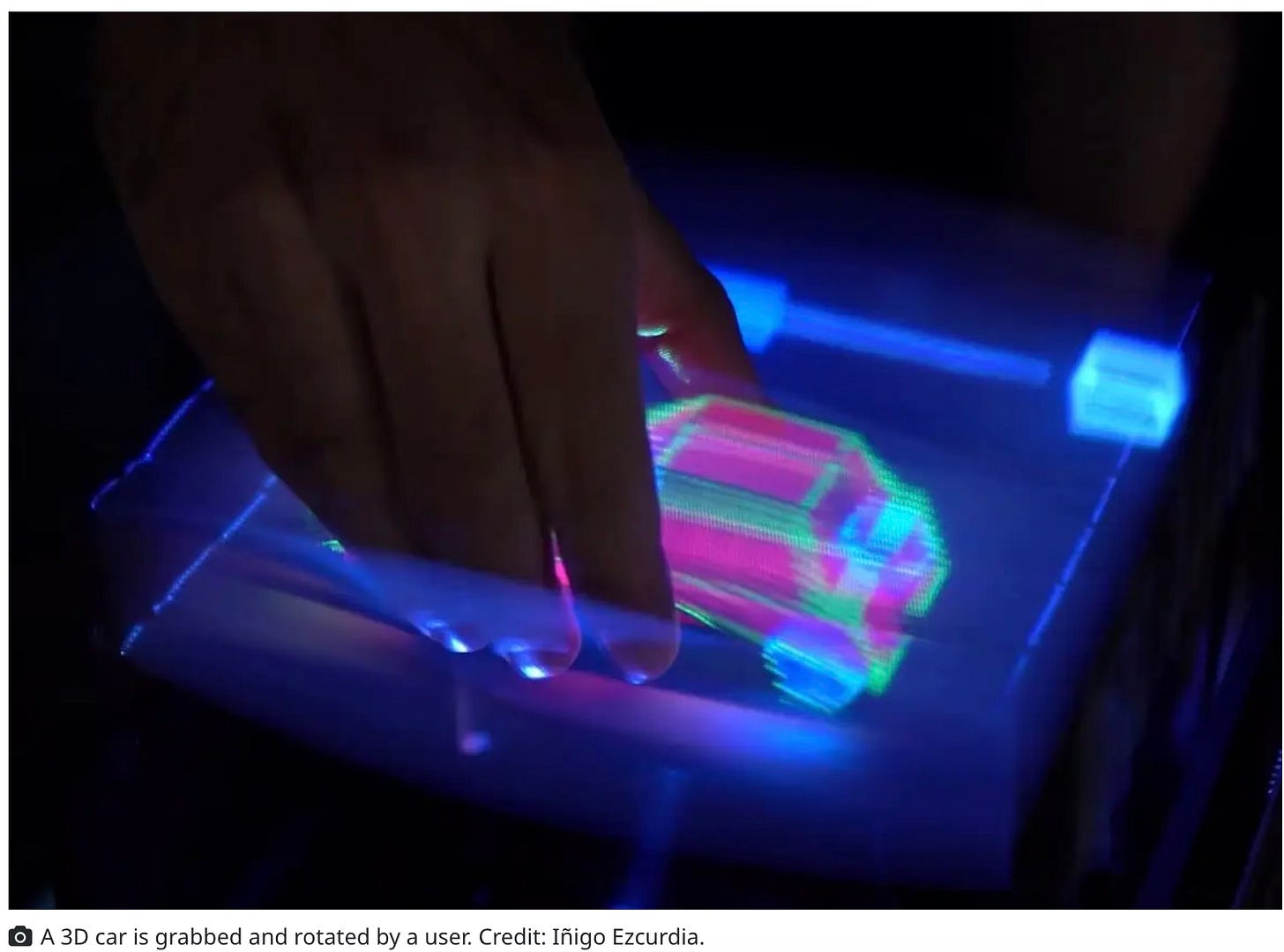

Holograms have been around for a while but they have not yet entered everyday use. A team at Public University of Navarra (Pamplona, Spain) and the Institute of Smart Cities have developed a three dimensional hologram that can be manipulated with your hands. This might be a step to bring holograms into everyday applications.

Holograms are volumetric displays that appear in mid air and can be viewed from a range of angles without the need for any special glasses or equipment. There are some commercial applications of holograms (e.g. Voxon Photonics in Australia) which allow museums and entertainment venues to provide shared visual experiences. These are view only experiences.

Volumetric displays have a fast oscillating sheet called a diffuser. Images are projected synchronously at 2,880 images per second. Images projected onto the diffuser at different heights are perceived as a complete volume.

The diffuser is usually rigid. Touching the diffuser whilst it is oscillating usually breaks the display (or injures the user). The team replaced the rigid diffuser with an elastic one. This allowed movement however elastic materials deform and require image correction.

The team solved this by applying real time image correction by predicting how the elastic diffuser would bend under pressure. The image now maintains its shape in spite of the distortion. This is a trick using both physics and perception. The result is an image that behaves like a real object that can be grasped and rotated or moved.

Applications for this new capability may find a home in education and training e.g. visualising and assembling the parts of an engine. Marketing may also find a use in product display and use.

Smart Airplane Windows

I am sure that we have all been on a plane, staring out the window wondering what city we are currently flying over or what mountain is that in the distance. US Optical systems company Zeiss have developed a new airplane window that may answer your questions.

Zeiss has developed a touch free holographic multifunctional smart glass system for aircraft windows. These windows might display flight information, geographical information or moving maps for commercial passengers. Smart glass panes rather than solid cabin dividers may also become interactive features.

To create this window, Zeiss has used a combination of micro optical structures and holographical optical components. Interactivity is enabled through the use of ultra violet and infra red based touches holographic buttons that respond to motion. Swapping out heavy physical dividers and bulky display tools with multifunctional smart glass can cut down the weight of the plane significantly.

Zeiss is also testing augmented reality HUD (Heads Up Displays) for pilots that reduce the need for them to look away from their surroundings. In this instance the smart glass uses infrared and microwave camera sensors to capture environmental data and transmit them directly into the pilot’s line of vision. This may be of great assistance in low visibility.

Stronger 3D Printed Metal

Researchers at the US National Standards Institute have found quasicrystals in a 3D printed aluminum alloy. Somewhat surprisingly the quasicrystals make the printed material stronger. The discovery of Quasicrystals lead to the 2011 Nobel Prize in Chemistry.

Quasicrystals are like ordinary crystals however there are a few key differences. A traditional crystal is a solid made from atoms or molecules in repeating patterns. There are only 230 possible ways for atoms to form repeating crystal patterns. Quasicrystals are different from these patterns. Their unique shape lets them form a pattern that fills the space but never repeats.

When 3D printing a metal a technique called powder bed fusion is commonly used. Metal powder is spread evenly in a thin layer. A laser then moves over the powder melting it together. Once a first layer is complete a new layer is commenced and the process is repeated.

3D printing creates shapes that are not possible with any other method. For example, GE 3D prints fuel nozzles for airplanes that are 25% lighter than previous versions (which comprised 20 parts that needed to be pieced together).

Aluminium melts at 700C. The lasers in 3D printers raise the temperature past the metal’s boiling point, 2,470C. This changes the properties of the metal, particularly as aluminum heats up and cools down faster than other metals. Adding zirconium to the aluminium powder prevented 3D printed parts from cracking making a stronger alloy.

Perfect crystals are weak. Their regular patterns make it easier for crystals to break. Quasicrystals change those regular patterns. By using defects in patterns they make the metal stronger. The aluminium quasicrystals have a five fold rotational symmetry from one angle, a two fold and a three fold symmetry from other angles. Five fold symmetries are very rare.

These findings may lead to a new approach to new alloy development. Quasicrystals can make the metal stronger therefore researchers will try to use these methods to intentionally make stronger, future alloys.

Energy from Rainwater

Two materials coming into contact can cause charged entities on their surface to gain charge. Rubbing a balloon on the skin for example creates static electricity. Similarly, water flowing over some surfaces can gain or lose charge.

A team at the National University of Singapore have demonstrated how to use rainfall to power LEDs using nothing more than a small vertical tube. Water that falls through a vertical tube generates power by using a pattern called plug flow.

In the team’s design, water flowed from the bottom of a tower through a metallic needle releasing rain sized droplets into the opening of a 32 centimetres tall, 2 millimeter wide vertical polymer tube. When the droplets hit the top they form short plugs of water separated by pockets of air. This pattern enhances charge separation as the water moves downward.

Electrical charges build up along the conductive inner surface of the tube. Electricity is captured by wires at both ends of the decent. Over 10% of the falling water’s energy is converted into electricity. This is over 5 times more effective than using a continuous stream of water. Using two tubes either sequentially or simultaneously generated double the electricity.

The team was able to channel water through four tubes and power 12 LEDs continuously for 20 seconds. Plug flow energy capture is likely simple to set up and maintain. It could become a part of urban rooftops with the resultant energy stored in batteries ready for use.

Paying it Forward

If you have a start-up or know of a start-up that has a product ready for market please let me know. I would be happy to have a look and feature the startup in this newsletter. Also if any startups need introductions please get in touch and I will help where I can.

If you have any questions or comments please comment below.

I would also appreciate it if you could forward this newsletter to anyone that you think might be interested or provide a recommendation on Substack.