This week we discover the secret behind the world’s toughest material. It has been used since the 1940’s however scientists have only just discovered the key to the outstanding toughness. We examine a new Nuclear Fission “Battery” that fits into a 40’ container and can power a neighborhood. Finally we look at a Russian Vtol that has no wings and a Flying Electric Car Race that hopes to become the F1 of Flying Electric Car Races.

The World’s Toughest Material

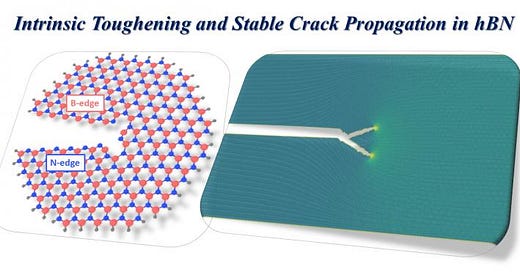

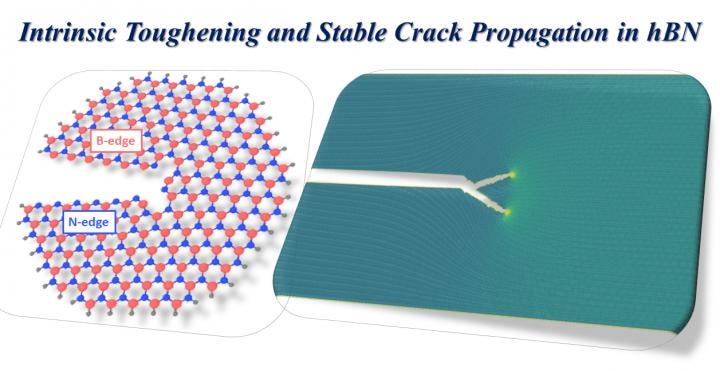

Researchers from Rice University and Nanyang Technological University (Singapore) have discovered the key to the outstanding toughness of hexagonal boron nitride. h-BN can withstand ten times the amount of force that graphene can. Graphene was considered one of the toughest materials on earth.

h-BN is a two dimensional material, just one atom thick. It was first used in cosmetics in the 1940’s however its’ use was abandoned due to cost. It returned to use in the 1990’s as technology reduced the cost of production. It is now used in cosmetic products because of its’ ability to absorb excess facial sebum and disperse pigment evenly. It is also used as a protective layer in electronics, as it insulated against electricity and can withstand temperatures of up to 1000 degrees celsius.

The researchers discovered that when subjected to stress, any breakages in the material branched like forks in the road, instead of traveling straight though the material. This meant that stress fractures were less likely to grow when additional stress is applied.

Like Graphene h-BN is arranged in interconnecting hexagons. The graphene is solely composed of carbon atoms whereas the h-BN hexagon structure has 3 nitrogen atoms and three boron atoms. This difference causes the cracks to branch off its’ path. This means it takes significantly more energy for a crack to be driven further through the material. Graphene breaks more easily and fractures travel through the material like a zipper.

Applications for h-BN include tear resistant flexible electronics such as wearable devices, foldable smartphones and wearable medical devices.

Nuclear Batteries

MIT researchers have developed a design for a very small modular nuclear fission reactor that they are calling a Nuclear Battery (the battery nomenclature is slightly misleading as it is a uranium based reactor that responds to demand rather than a store of energy).

I have long believed that very few if any new nuclear fission reactors will be built despite their low carbon status. The typical nuclear reactor takes at least 10 years to build and more often than not, they are beset by delays due to the technical difficulty of construction. The time from proposal to construction can take up to 20 years. Technology is highly likely to have made the reactor obsolete by the time that it is built, rendering the projects economically unfeasible.

Typically reactors are very large. In 2018 there were 98 operating in the US ranging from 582 megawatts to 3,937 megawatts. The Nuclear Battery is a very small modular reactor, designed to produce 10 megawatts of power and fit into a standard 40 foot shipping container.

The modules will be built in a factory and subjected to onerous safety checks before being deployed. The systems have a very robust steel shell containment structure to protect against release of radiation. The reactor has a high surface to volume ratio which makes it easier to keep the system cool. The system is designed to be maintenance free and only needs attention once every 5 to 10 years.

The systems are very small enabling them to distributed throughout the grid to provide an on demand alternative to intermittent solar and wind sources. Factory built they are quick and easy to deliver and install. The next step is to build a pilot at the Idaho National Laboratory (a US nuclear reactor testing site).

Whilst I still doubt that I will ever see one at the of my street powering the neighborhood, it is quite possible that this type of reactor may find use in Mining operations, desalination plants and large energy heavy manufacturing settings.

A new Russian Flying Car

The Cyclocar is an all electric autonomous aircraft or Vtol, that flies forward thanks to its’ four cylindrical propellors. It will be able to transport up to six passengers with a maximum payload of 600kg (we might need to start weighing some passengers before takeoff).

Measuring 6.2 meters by 6 meters and with a maximum speed of 250km/h the Vtol has a range of 500 kilometers. The vehicle can operate quietly in urban environments and land on surfaces with up to a 30 degree incline. Designed for civilian and military uses including urban mobility, search and rescue, police work, fire fighting and tourism the Vtol is easy to fly remotely or with an onboard pilot. Developed by the Russian Government the first applications will be military in nature. Test flights start in 2022 and production is planned for 2024.

Flying Electric Car Race

The first unmanned flying electric car test races have been held in South Australia. The developer hopes to build the F1 of flying electric car races. The first 3 races will be held in late 2021 at as yet unnamed international locations.

Up to 4 teams, each with 2 remote pilots will compete over locations inaccessible to traditional motorsport. The Alauda Mk3 (shown above) has a top speed of 250km/h and a greater thrust to weight ratio than a F15 fighter jet. Piloted races are in their future plans.

Paying it Forward

If you have a start-up or know of a start-up that has a product ready for market please let me know. I would be happy to have a look and feature the startup in this newsletter. Also if any startups need introductions please get in touch and I will help where I can.

If you have any questions or comments please email me via my website craigcarlyon.com or comment below.

I would also appreciate it if you could forward this newsletter to anyone that you think might be interested.

Till next week.

The flying car looks perfect for Blade Runner applications. Battery flying time might be short though.