This week we discover a new and cheaper way to produce a natural low calorie sugar. We investigate a shape shifting fibre that can adapt to changes in temperature. Finally we look at some game changing developments in the chips that drive AI. Faster and cheaper alternatives to the current high performance chips.

Low Calorie Sugar

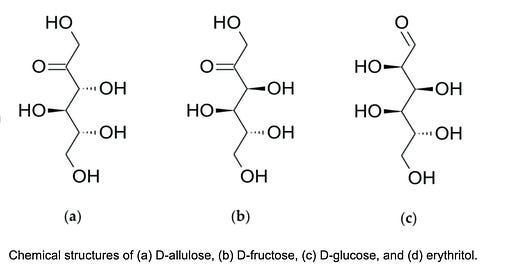

The sugar that we use every day to sweeten almost everything is sucrose. It is easy to make and cheap. An alternative sugar is allulose. It is 70% as sweet as sucrose however it contains 10% of the calories. Some studies have shown allulose can improve blood glucose levels and help in weight loss for people with type 2 diabetes. The problem is that the yield level of allulose in current production is very poor. This makes it very expensive. In the US it retails for approximately US$21 per kilo.

A team at University of California, Davis have made a breakthrough in allulose production which offers high yield and scalability. These two qualities may make it a viable and healthier sugar substitute.

Allulose is a rare sugar that only exists in minute amounts in a few plants such as wheat, figs and raisins. It has the same texture and mouthfeel as sucrose with only 0.4 calories per gram (v 4 calories per gram for sucrose). It is a monosaccharide or single molecule of sugar and thus undergoes a different digestion process in the body than sucrose. Roughly 70% is absorbed by the small intestine and is expelled via urine within 24 hours. The balance goes through the large intestine and leaves the body within 48 hours. This is why it doesn’t affect blood glucose or insulin levels.

The team at US Davis used a common gut bacteria which had its’ metabolic processes edited so that when the bacteria was fed glucose, it converted it to allulose. The yield was 62% with purity of 95%. The bacteria had the correct metabolic process naturally however it had to be turned on by the scientists.

The process is sustainable, cost effective and can be scaled using current production infrastructure and biochemistry techniques. It may be the breakthrough that we need to help end the obesity epidemic.

Shape Shifting Fibre

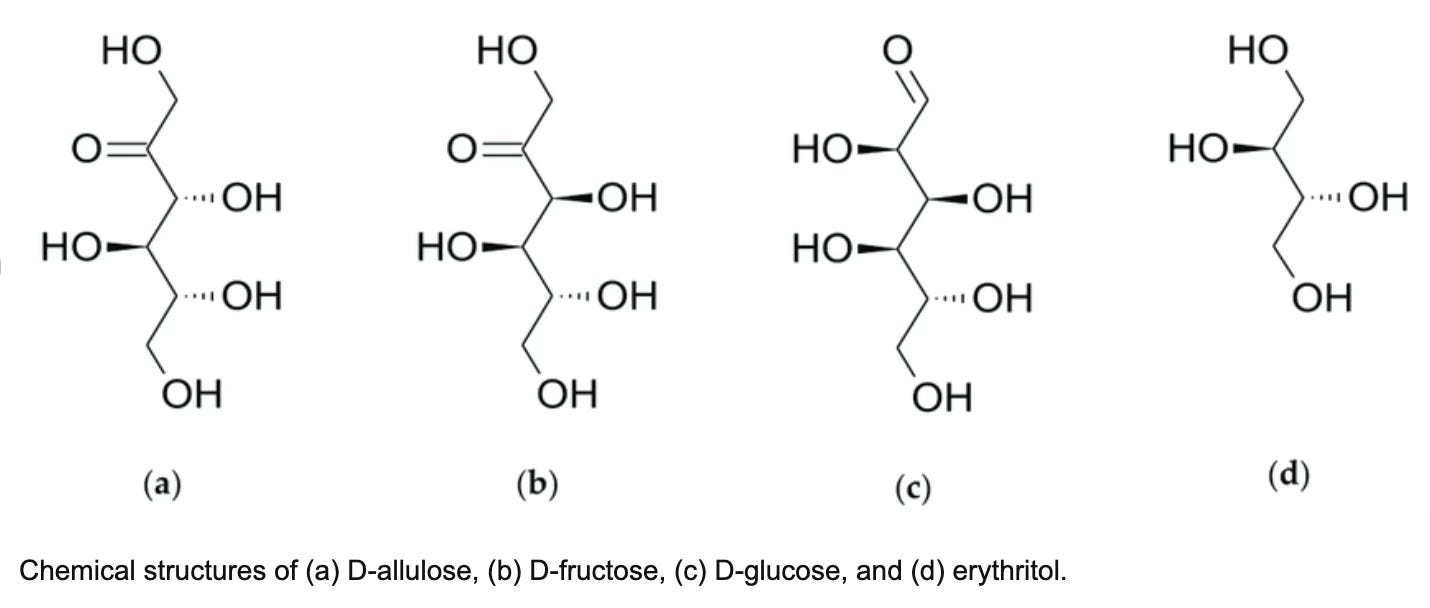

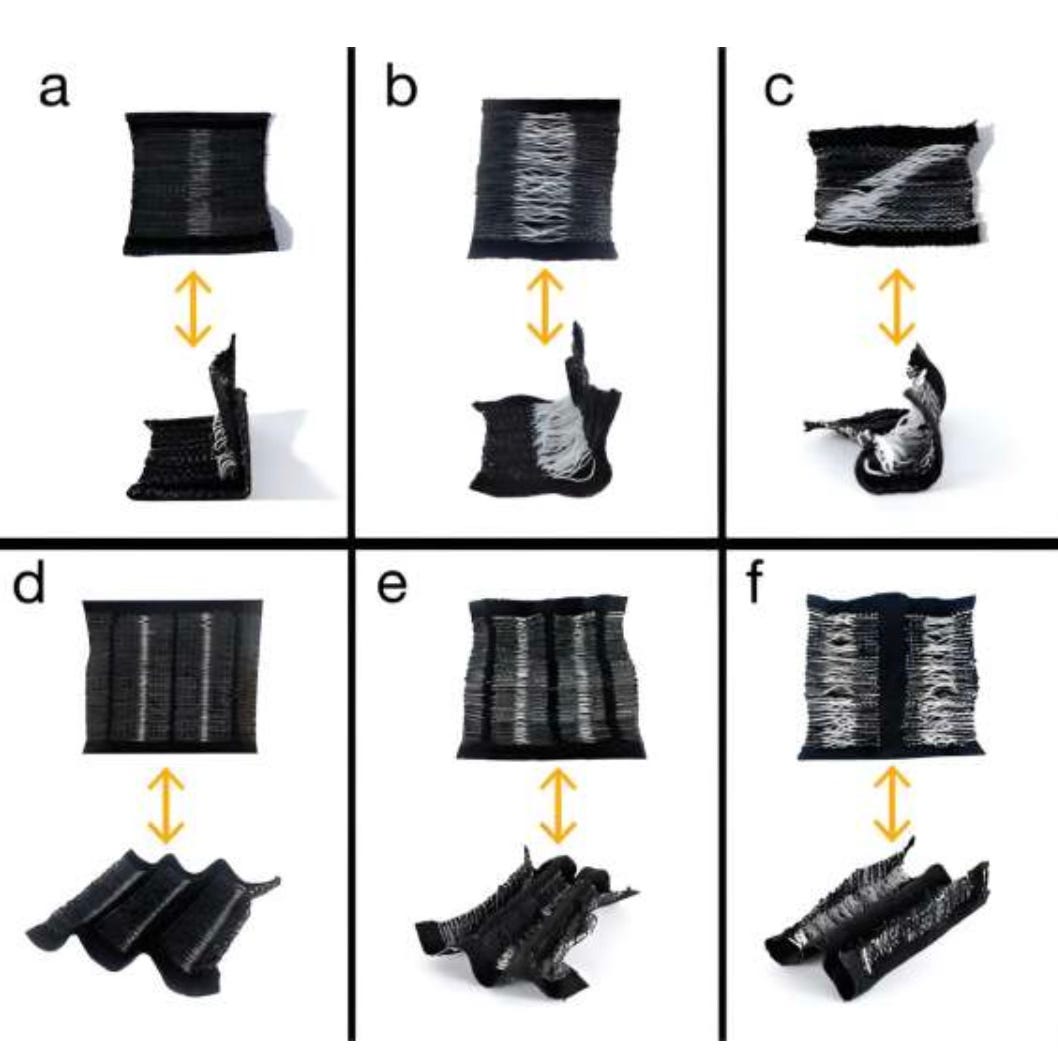

Teams at MIT and NorthEastern University in Boston have developed a fabric that expands when the temperature rises and contracts when the temperature falls. A jacket made from this fabric may one day contract and keep you warmer when the temperature drops and self reverse without any embedded sensors when the temperature rises again.

The teams used a material known as a liquid crystal elastomer (LCE). A liquid crystal is a series of molecules that can flow like a liquid however when they are left to settle they stack into a periodic crystal arrangement. This crystal structure was incorporated into a elastomer network which is stretchy like a rubber band. As the LCE heats up the crystal molecules fall out of alignment and pull the elastomer network to contract. When the heat is removed the molecules return to their original length.

The researchers can control the properties of the fabric, such as thickness or the temperature that it adjusts, via the mix of chemicals used to synthesize the LCE. The material is able to be used at skin safe temperatures which make it ideal for wearable fabrics.

The fibre can also be combined with a conductive thread which could act as a heating element when electric current is run through it. This gives a user greater control over the textiles form. For example, a heart rate sensor could be attached and the fabric could react to heart rate changes.

The low cost fibre is fully compatible with textile manufacturing machines, weaving looms, embroidery and industrial knitting machines. It can be manufactured by the kilometer. It is easy to incorporate a range of sensors for yet to be dreamt of applications.

AI Computer Chips

With the current explosion in AI applications there is a corresponding explosion in the amount of computing power and electricity required to run these computationally and training intensive programs. Two recent breakthroughs may reduce the power required and increase the speed of computation.

IBM Chips

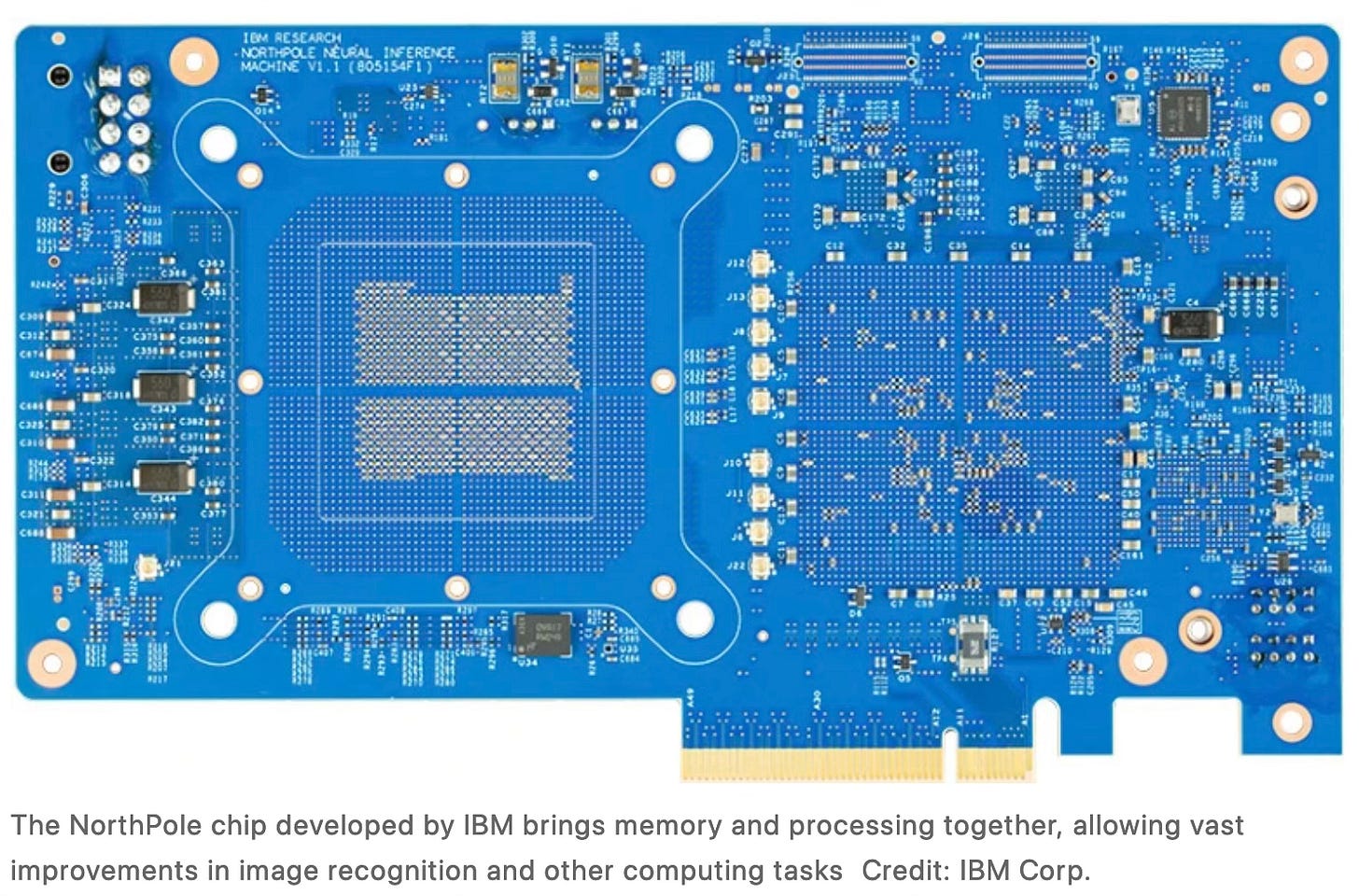

IBM have developed a new chip called NorthPole which eliminates the need to frequently access external memory. This speeds up tasks such as image recognition whilst consuming vastly less power.

NorthPole runs neural networks, multi layered arrays of simple computational units programmed to recognize patterns in data. A bottom layer takes in the data such as the pixels in an image. Each successive layer detects patterns of increasing complexity and passes that information onto the next layer. The top layer will produce an output that will tell us what the image is.

Other chips that can manage these calculations have to access external memory which takes time and power. This is known as the Van Neumann bottleneck after John von Neumann who was the original architect of separate processing and memory units in computers.

NorthPole has 256 computing units (or cores), each of which has its’ own memory. This structure will allow the computer to use 1/25th of the power of current state of the art AI chips.

NorthPole has 224 megabytes of RAM which is not enough for the current Large Language models such as ChatGPT (which requires several thousand meg even in the most stripped down versions, hence they are all managed in the cloud). The team expects that the chip will be most useful in speed critical applications such as self driving cars.

Machine Learning Transistor

Most machine learning and AI processing happens in the cloud due to the high computational and energy needs of the programs. Researchers at NorthWestern University in Chicago have developed a nano device that can classify data for machine learning systems.

Currently sensors collect data and send it to the cloud for analysis. Once analyzed the data is labeled and ready for computation. This takes time and energy in transition and computation. The new device is so energy efficient it can be incorporated into a wearable and used for real time detection and data processing.

Most existing transistors are made in silicon. The new device is composed of two dimensional sheets of molybdenum disulfide and one-dimensional carbon nanotubes. The design allows for the device to be quickly turned and reconfigured in real time allowing for multiple steps in the data processing chain to be completed. Traditional transistors can only perform one step.

The team use these “mixed-kernel heterojunction transistors” to analyze ECG datasets and label six different types of heartbeats; normal, atrial premature beat, premature ventricular contraction, paced beat, left bundle branch block beat and right bundle block beat. Using two of the micro transistors and a set of 10,000 ECG samples the device was able to classify abnormal heartbeats with 95% accuracy. Current machine learning approaches would require 100 traditional transistors. The new devices used 1% of the energy of the traditional transistors.

Once the devices have been built into wearables they will be able to run analysis on the device. This keeps data local and private. Problems can be detected much more quickly and action taken more promptly.

It is unclear if the devices can only be used in portable devices for smaller applications. If the devices can handle video and other training requirements with the corresponding drop in power consumption it would be a massive step forward in large AI model training. In 2021 Google spent 10 to 15% of its entire energy budget on AI training. That percentage will be much higher now only 2 years later.

Paying it Forward

If you have a start-up or know of a start-up that has a product ready for market please let me know. I would be happy to have a look and feature the startup in this newsletter. Also if any startups need introductions please get in touch and I will help where I can.

If you have any questions or comments please comment below.

I would also appreciate it if you could forward this newsletter to anyone that you think might be interested.

Till next week.

It seems AI will soon use more energy than Bitcoin mining.