This week we will investigate Heat Pumps, an old but increasingly topical technology that is improving the efficiency of heating and cooling our homes. We discover a Linear Energy Generator which was developed following a question posed by a Stanford Professor 20 years ago. We find out how to reduce the cost of pumping liquids by 22% and we examine some robotic fingers that may replace x-rays and ultrasounds.

Heat Pumps

Heat Pumps are not new, they were invented in the 1860’s, however as the reliance on gas for heating is being reduced, particularly in Europe, I thought it worthwhile to have a quick look at what they are and how they work. We will see a lot more heat pumps in our houses all over the globe in the coming years (particularly in the Northern Hemisphere).

Heat pumps are electric powered and used to move heat around a building to either cool or heat the building. Newer models of heat pumps are more efficient and better able to handle cold weather.

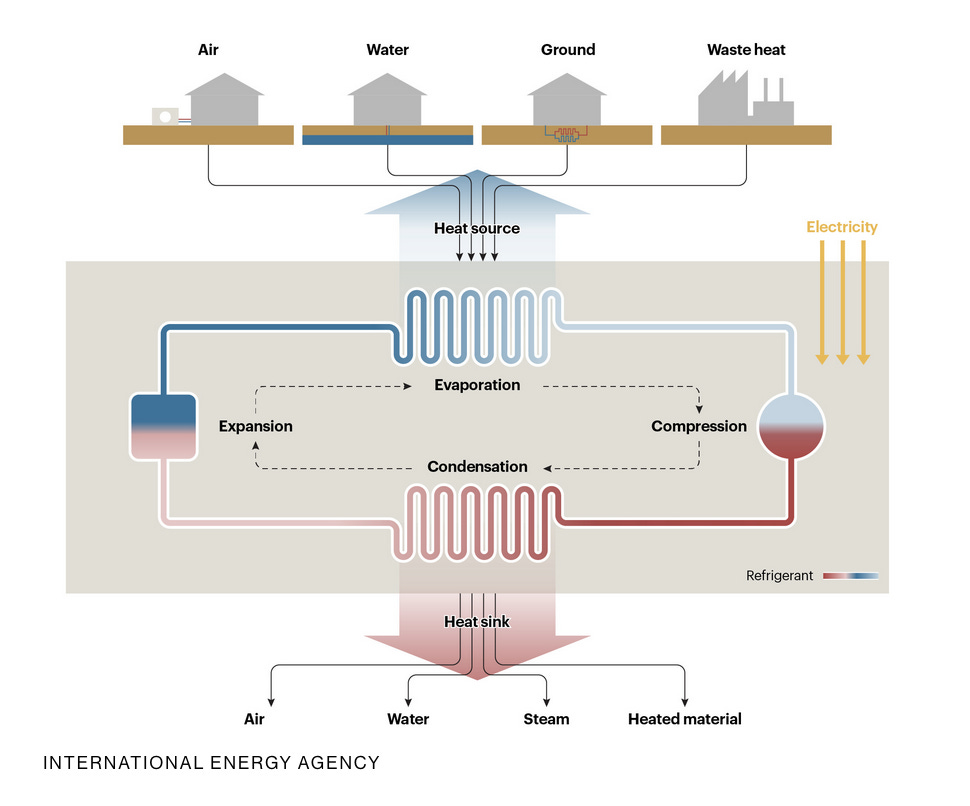

A refrigerant is moved through a circuit in the building, soaking up and releasing heat as it goes. As the refrigerant is moved through the heat pump its’ compressed and expanded, switching between liquid and gas forms. This allows the gathering or release of heat during the cycle.

Initially the refrigerant flows through a heat exchanger, past the outside air and warms up enough to starting boiling and change from a liquid to a gas. The gas then travels through a compressor, squeezing the gas into a smaller volume, increasing the pressure and the boiling point. This also warms the gas. Now the gas is roughly 38C which is warmer than the room indoors. The gas then travels through another heat exchanger to release the heat into the room. A fan is used to distribute the heat and the loss of heat turns the refrigerant back into a liquid.

Heat pumps do work in all climates however they are not as effective in extreme cold (despite this 60% of buildings in Norway use heat pumps for heating). New refrigerants, compressors that work at higher pressures and better heat exchangers have all improved the effectiveness of heat pumps in recent years. Some newer models source heat from underground further increasing effectiveness in colder climates.

Linear Energy Generator

About 20 years ago a Stanford Professor gave some of his PHD students a challenge “what is the most efficient and practical way possible to convert chemical bond energy into useful work?”

We burn fuels to release this energy. Fuel cells use catalysts to trigger the chemical reactions that will release the energy however catalysts are expensive and degrade over time. They also respond poorly to rapid changes in load. The students already knew that energy could be released by compressing a mixture of air and fuel however it was difficult to control efficiently.

A simple process in reality, put fuel in a box, squeeze the box, molecules collide and when the box expands more force is delivered outward than the initial squeeze. Repeat the process as often as needed. The first prototype was built in 2008. In 2010, Mainspring Energy was founded to develop a commercial system.

The key is being able to manage the compression for the gas being used. If the compression continues after the reaction happens, it fights against the pressure thus wasting energy. If compression stops too soon, the reaction never happens. The heat of the day will also change the optimal pressure required.

Conventional engines harvest energy by turning a crankshaft. That mechanism makes it difficult to adapt to changing loads and compressions from different fuels. The team designed a system to directly generate electricity from the expansion motion. The machine is completely different from conventional electricity generators hence the new name “Linear Generator”.

The power generation works like regenerative braking in electric cars (which came out of Formula 1 racing technology). An electric car’s motor acts in reverse as a generator to convert the car’s motion as it slows, into electricity which is feed into the batteries.

The computer controller can hit the desired turnaround position within 1/10th of a millimeter and then target a different position (when a different fuel is used) on the next cycle. The system will determine the turnaround position just before the end of each cycle. This maintains an optimum reaction process throughout the entire load range. If power demand drops the fuel feed will slow immediately. The system will deliver the right amount of power.

The working system pairs with rooftop solar arrays. When the sun is shining the generator turns itself off, when the sun is behind a cloud the generator immediately springs into action.

The newer versions of the system have been built to accommodate a range of gas inputs including, natural gas, biogas, hydrogen, ammonia, syngas and alcohols. In 2020 the first commercial system was deployed into a national retail chain in the US. Other installed systems have been run on hydrogen, ammonia, a landfill project uses the waste gas produced in the landfill (which is otherwise released into the atmosphere). Later this year wastewater treatment plants and dairy waste digesters will start using the Linear Generators. Electric truck charging systems and larger utility scale systems in the megawatt scale are in development and early deployment.

More Efficient Pumping

A team from Okinawa Institute of Science and Technology and Polytechnic University of Milan have developed a more efficient method of pumping liquids, significantly reducing the cost of transport.

The smooth and efficient flow of a liquid is called a Laminar Flow. When you slowly turn a tap on, the flow is streamlined, smooth and energy efficient. However as the tap moves to full blast the flow becomes a Turbulent Flow which wastes a lot of energy. Reducing turbulence will reduce the cost of moving fluids through pipes. This applies to water, liquid hydrogen and natural gas and oil.

The researchers simulated the flow of a liquid through a pipe and were able to test a variety of different scenarios where the duration of time that a pump was turned on, the intensity of the pump and the overall length of each pump cycle was varied. They found that long cycles characterized by a short intense pump that initially accelerated the fluid flow followed by a long phase where the pump was switched off and the fluid slowed down caused the fluid to remain in the Laminar state for longer.

The team was able to reduce the amount of energy required to pump liquids through a pipe by 22%. Further study of the fluids behavior under various types of pumping may reduce the cost further.

Bionic Fingers

A team at Wuji University in Guangdong in Southern China have developed a way to use a robotic touch instead of using x-rays or ultrasound to image the insides of humans. The team developed a robotic finger that can create 3D maps of the internal shapes and textures of complex objects by touching their exterior surface.

The robotic finger scans an object by moving across it and applying pressure. Like the constant stream of prods and pokes you receive at the doctor during a physical exam. With each robotic poke the carbon fibers in the finger compress and the degree to which they compress provides information about the relative stiffness or softness of the object below. This information is then displayed as a 3D map.

The team created 3D profiles of simulated human tissue. The tissue was composed of a skeletal component made of hard polymers and a soft silicone layer representing muscle. The robotic finger was able to reproduce the tissue’s structure and locate a simulated blood vessel beneath the muscle layer.

The team also explored the ability of the robotic finger to diagnose issues in electronic devices without opening them up. By scanning the surface of a defective electronic device with the robotic finger the team were able to create a map of the internal electrical components and pinpoint the location where circuits were disconnected or holes were miss drilled without opening the case.

Paying it Forward

If you have a start-up or know of a start-up that has a product ready for market please let me know. I would be happy to have a look and feature the startup in this newsletter. Also if any startups need introductions please get in touch and I will help where I can.

If you have any questions or comments please comment below.

I would also appreciate it if you could forward this newsletter to anyone that you think might be interested.

Till next week.