Welcome to the 300th Edition of “What’s on Craig’s Mind?”. When I started I had no idea this would last this long and now I have no idea how much longer it will last. Time will tell. Thanks for coming on this journey of discovery and learning with me.

This week we discover a new process for manufacturing transparent Aluminum. We investigate a slime that can produce electricity when squished and we consider self assembling sofas. Not yet at your local Ikea but they can’t be far away. Finally we examine a new blood test for detecting Pancreatic Cancer, one of the most difficult cancers to detect early due to the lack of symptoms.

Transparent Aluminium

Transparent Aluminium Oxide (TAIOx) is an incredibly hard and resistant to scratch material used for protective coatings on electronics, optical sensors and solar panels. It was even written into Star Trek where it was used for starship windows and spacefaring aquariums.

TAIOx is currently very expensive and complicated to manufacture. It requires high powered lasers, vacuum chambers or large vats of dangerous acid. A team at Ateneo de Manila University have developed an alternative method of manufacture.

Rather than dip entire sheets of metal into acidic solutions the team applied micro droplets of acid onto small aluminum surfaces and applied an electric current. Two volts was enough to transform the metal into glass like TAIOx.

Called droplet scale anodization, the process is simpler, cheaper and more environmentally friendly with less energy use. The special effect caused by the electric current is called “electrowetting”. The electric field changes the properties of the liquid droplet. This allows precise control over the anodization process.

The new process might make TAIOx cheaper and more accessible for applications in everything from touch screens and lenses to coatings for vehicles and buildings. Researchers now have a method for converting metal surfaces into insulating transparent layers. This advance could led to a wide range of new applications not yet considered.

Electricity Producing Slime

A team from the University of Guelph in Canada have developed a slime like material that produces electricity when compressed. The slime is able to form itself into different structures at the microscopic level. It can either be arranged like a sponge, layers like a lasagna or in hexagonal form.

The prototype is 90% water plus oleic acid (Omega 9) and Lysine (an amino acid found in proteins in the body).The slime is clear and odorless. The slime doesn’t make much electricity however there are multiple applications where it could be beneficial.

A cut on the skin will create a stress deformation inside the skin. This generates electric fields. These electric fields call the healing cells to the injured area and allows healing to occur. This slime will facilitate the healing process. Th slime is made from materials common in the body so it will not harm you.

Additional uses include installing it under floors to generate energy when walked upon, in a shoe insole to help analyze your gait and for synthetic skin to help train robots to know how much pressure to use when checking the pulse of a patient.

Self Assembling Sofas

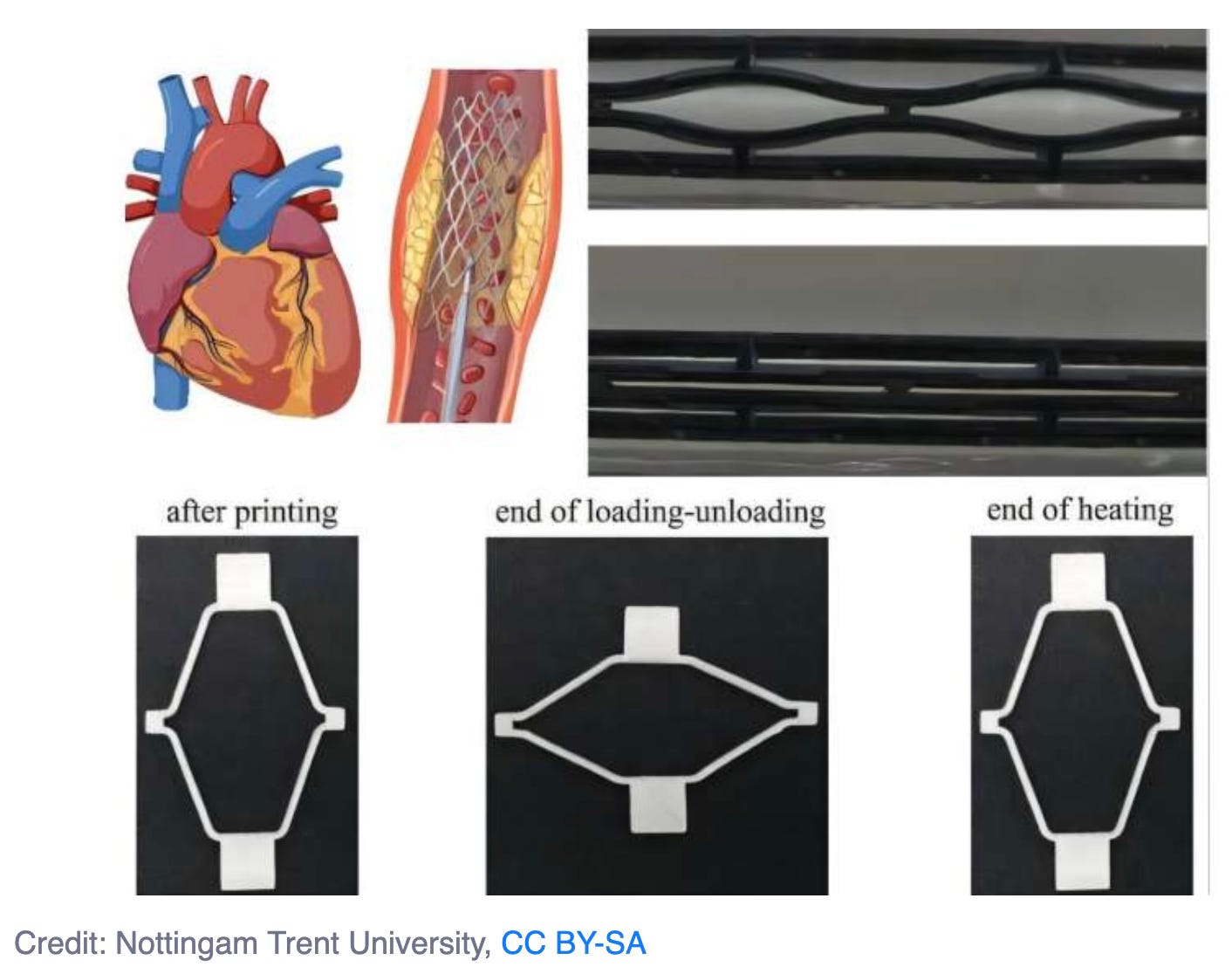

Just when you thought Ikea had flat packed the life out of everything a team at Nottingham Trent University have developed a method for converting a flat sheet into a full sized sofa by applying heat with a hairdryer. Called 4D printing it is essentially 3D printing with an element of time.

The technique involves 3D printing adaptable objects from materials such as polymers or alloys that can bend or twist or transform entirely when they come into contact with heat or moisture. The idea opens up possibilities in medicine, aerospace, robotics and construction.

The technique could allow for stents and implants that will adapt to the patients needs in real time. The Biomet4D project in Madrid is working on this possibility. They are developing smart biodegradable metallic implants for people with damaged or defective bones. The implants can change shape and expand as the bone grows, supporting it more effectively than a static implant. A team in China is working on 4D printed hydrogel capsules for drugs, whose structure stays in tact until the patient’s temperature reaches a certain temperature. Then the drug is released.

4D materiais in robotics and wearables allows functionality to be adjusted in response to their environment. A team at Harvard have developed self folding robotic devices that change shape when exposed to heat. This may have application in environments that are difficult to access such as deep in the ocean. A team at Deakin University in Victoria is developing 4D robotic joints with variable stiffness to help with rehabilitation.

The team in Nottingham is also woking on materials for boat and car fenders whose shape can be restored by adding heat. An easy way to remove dents from your car and to make a shape adaptive finger splint for your broken fingers. The team is also developing the materials for the aforementioned sofa sheets. Commercial applications will help speed up funding into this area.

Blood Test for Pancreatic Cancer

A team at Oregon Health & Science University have developed a test which uses a small blood sample to detect changes in protease activity; a key indicator of pancreatic ductal adenocarcinoma (PDAC), the most common form of pancreatic cancer.

Pancreatic cancer has few symptoms and therefor is often diagnosed at an advanced stage. The current tests for pancreatic cancer are suitable for conforming prognosis however they are not sensitive enough for early detection.

The new test called PAC-MANN (for protease activity based assay using a magnetic nano sensor) fills the gap in the current testing by identifying signs of cancer related activity in the blood. This allows earlier identification of possible cancers and opens up more tools for treatment and survival.

The team used samples from 350 patients that either had pancreatic cancer or were at high risk pancreatic cancer. Specific proteases that were more active in the blood from people with PDAC were identified. Once these proteins were identified a test that could specifically detect pancreatic cancer was developed.

The PAC-MANN test was able to correctly identify patients with pancreatic cancer v healthy patients and those with non pancreatic issues 98% of the time. Early stage cancer was identified 85% of the time when used with the CA 19-9 test currently used.

Additionally the PAC-MANN test can track how well treatments are progressing. The test only requires a small amount of blood making it less invasive and cheaper to administer on a regular basis. A tiny blood sample provides a simple fluorescent readout making the test quick and easy.

Paying it Forward

If you have a start-up or know of a start-up that has a product ready for market please let me know. I would be happy to have a look and feature the startup in this newsletter. Also if any startups need introductions please get in touch and I will help where I can.

If you have any questions or comments please comment below.

I would also appreciate it if you could forward this newsletter to anyone that you think might be interested or provide a recommendation on Substack.