Deep Mind forecasts the Weather, 3D printed bones, tendons and ligaments and a Cooling Ceramic

November 23

This week AI takes on the task of weather forecasting. We investigate the new developments with AlphaFold, Google’s protein folding AI. We examine some 3D printed bones, ligaments and tendons. Finally we discover a new ceramic material that can help keep buildings cool.

Deep Mind forecasts the Weather

Weather forecasters are the most under appreciated profession. Forecasting weather is an extremely complex and changeable beast. It means that they can sometimes be wrong.Forecasts are right often enough that we will rely on them but wrong often enough to cause us to complain.

Current forecasting methods rely on the Numerical Weather Prediction model formulas. These are physics based equations covering a massive number of variables. Data is collected by weather stations, satellites and ocean based equipment. The models project trajectories of global heat, air and vapor trails. Experts then analyze and constantly update the algorithms to try and make an accurate forecast. The process is time consuming, costly and energy intensive. Not to mention often wrong.

DeepMind has improved upon this approach by training machine learning models with 39 years of weather data. The physics based equations were dumped. The neural network is called GraphCast and it is able to crunch historical data at 1,000 to 10,000 times faster than the conventional systems.

In the troposphere, the part of the atmosphere where we live, GraphCast outperformed the conventional models on 99% of the 1,380 measurements used to predict weather. Based upon 2018 data forecasts and actual data, GraphCast generated forecasts for 10 days in advance in less than a minute. The results showed a higher degree of accuracy than the traditional methods.

GraphCast currently doesn’t perform well for highly local forecasts, i.e. will it rain in your neighborhood today however it works well over larger events such as tropical cyclones and unusual swings in temperature (which can be deadly). Algorithms will improve as more and more local data becomes available.

Use all those old weather forecaster jokes now whilst you can. In 5 years the kids will have no idea what you are talking about when you joke about inaccurate weather forecasts.

AlphaFold update

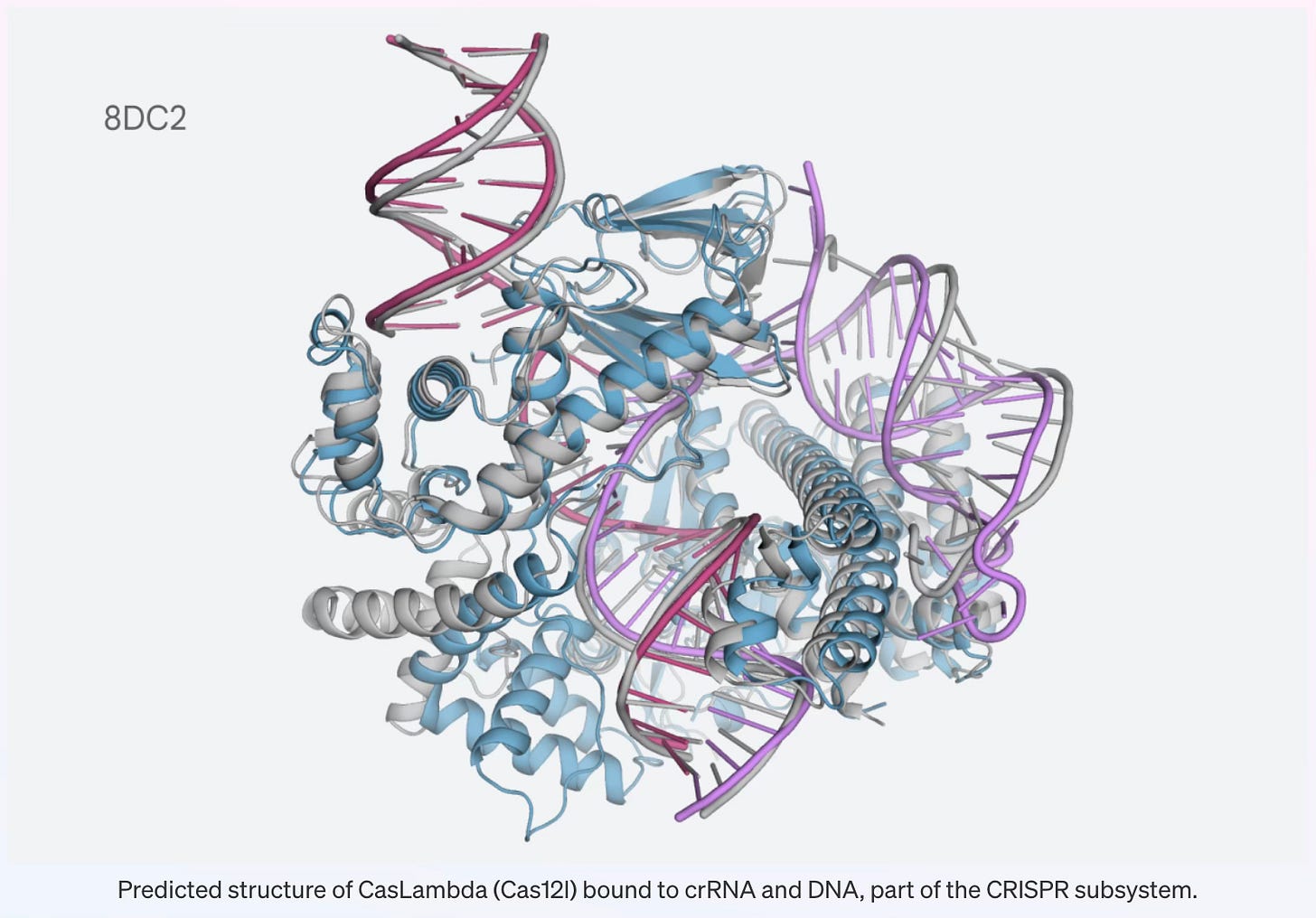

AlphaFold is the DeepMind project that predicted the way that proteins would fold. How proteins fold is critical to the development of new drugs and cures for many diseases.

It is now 3 years since AlphaFold was first released. The new update makes predictions for nearly every molecule in the Protein Data Bank. This includes ligands, proteins and nucleic acids (DNA and RNA). These different structure types are essential for understanding the biological mechanisms that happen within the cell.

The updated model will help accelerate breakthroughs in understanding deisase pathways, mechanisms for drug design and protein engineering and drug design. Over 1.4 million people have used AlphaFold to date and it has been helpful in developing new malaria vaccines, advancing cancer drug discovery and developing plastic eating enzymes to tackle pollution.

3D Printed Bones, Ligaments and Tendons

3D printing has been around for quite some time now. We are starting to move into the rapid improvement phase of this technology. Previously 3D printing was limited to fast curing plastics. More recently slow curing plastics have become suitable. Slow curing plastics have enhanced elastic properties and are more durable and robust. This opens up a wide range of potential uses.

Using the new technology a team at ETH Zurich have printed a robotic hand with bones, ligaments and tendons. Each are made from different polymers which can now be printed at one time rather than separately.

3D printers typically produce objects layer by layer. A nozzle deposits a material in a viscous form and a UV lamp cures the layer. A scraper removes surface irregularities. This only works with fast curing polymers. To allow the use of slow curing polymers the team added a 3D laser scanner to check each printed layer for irregularities. This feedback mechanism allows the printer to compensate for those irregularities.

The robotic hand can grasp objects and move all its’ fingers. The new 3D printing technology was developed by Inkbit, an MIT spin off.

Cooling Ceramic

A team at City University of Hong Kong have developed a passive radiative cooling (PRC) material that allows energy free cooling. It is cost effective, durable and versatile. The material is known as a cooling ceramic.

The ceramic has a unique hierarchal porous structure which is easily fabricated using inorganic materials such as alumina. A two step process involving phase transition and sintering (compacting a material to form a solid mass) are used. No specialist equipment or materials are required.

Optical properties determine the cooling performance of PRC materials in two wavelength ranges, solar range and mid-infra red range. Efficient cooling requires high reflectivity in the solar range and the ability to radiate heat in the mid-infrared range.

The cooling ceramic scatters almost all wavelengths of sunlight (99.6%) and achieves mid-infrared thermal emissions of 96.5%. The material has outstanding fire resistance of temperatures in excess of 1,000C making it a suitable material for building cladding. The material is also weather resistant, chemically stable and has mechanical strength.

Applying the cooling ceramic on the roof of a house can reduce the energy required for cooling by 20%. The team is now working on applications in textiles, energy systems and transportation.

Paying it Forward

If you have a start-up or know of a start-up that has a product ready for market please let me know. I would be happy to have a look and feature the startup in this newsletter. Also if any startups need introductions please get in touch and I will help where I can.

If you have any questions or comments please comment below.

I would also appreciate it if you could forward this newsletter to anyone that you think might be interested.

Till next week.

But still can we print the Terminator yet? (and will it melt in a molten steel vat)