If we wish, as they say in Star Trek, “To go where no man has gone before” then we will need a different type of rocket engine and fuel than the traditional chemical rocket propellants. This week we look at the development of an Antimatter Drive for spaceships. We will also look at several new developments in robotics that are making several tasks simpler and cheaper.

Harnessing Antimatter to reach the Stars

Firstly what is antimatter. Physics defines it as a form of matter that is identical to ordinary matter except that it is composed of anti electrons, antiprotons and antineutrons. Think of it this way, if - is the opposite of +, then antimatter is the opposite of matter. Antimatter is quite rare in the universe but it does exist in space.

Minuscule amounts of antimatter are created every day in particle accelerators around the world. To date total global production is only a few nanograms. In 2010 antimatter hydrogen particles were stored for the first time at CERN. Unfortunately production and storage of Antimatter is prohibitively expensive and extremely difficult. However some Antimatter exists in the Van Allen belt (a zone of energetic charged particles) which are captured and held in place surrounding the earth by our planet’s magnetic field.

If antimatter and matter collide they will annihilate each other and give off various proportions of intense photons (gamma rays), neutrinos and sometimes, less massive particle-antiparticle pairs. The majority of the energy emerges in the form of ionizing radiation.

Positron Dynamics is attempting to harness the annihilation of matter and antimatter to power spaceships to travel to the stars. The small amounts of fuel and the massive energy output makes it an ideal fuel for interstellar travel. The Trekkies amongst you will remember that the warp drive on the Enterprise was powered by Antimatter.

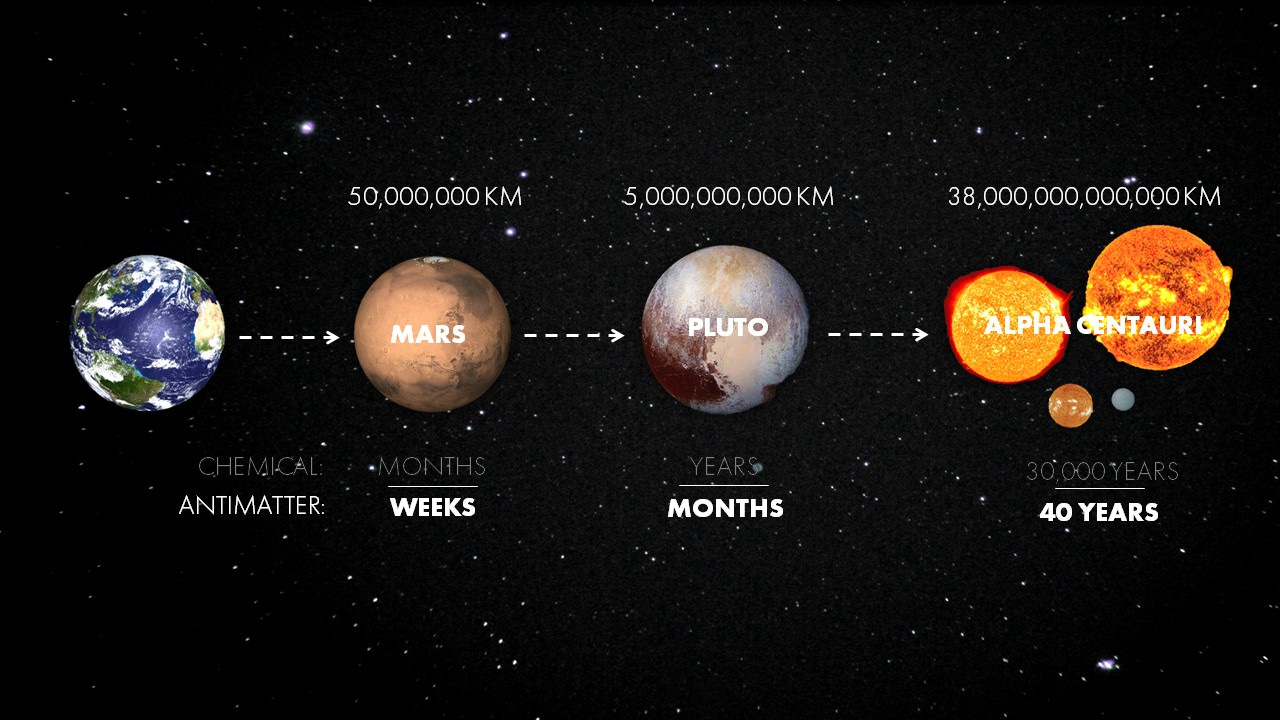

Using Antimatter to power a spacecraft is vastly more efficient than the traditional chemical rockets that we currently use.

2 of the 3 Co-Founders of Positron Dynamics obtained their Phd’s at Australian National University. The company has raised capital from a range of investors including Peter Thiel (one of the initial funders of FaceBook). Ryan Weed, Positron Dynamics CEO’s TED talk can be found here.

Robotic Vision for Warehousing

Fanuc America has just released their latest vision sensing system for Industrial Robots. The sensor is lightweight and works as a fixed or robot mounted 3D vision camera. The system can snap 3D images over a range of 2 meters which is ideal for picking goods from storage bins.

Fanuc builds all of its’ vision hardware and software for Fanuc robots. For example their M-710ic/45m robot can handle payloads ranging from12 kilos to 70 kilos. It has a 2.6 meter reach and is capable of high speed operation. The slim wrist and rigid arm allows it to work in tight spaces. Combined with the long reach and six axis articulation it is suitable for bin picking, palletizing, packing and other warehouse applications.

A Third Arm

At the University of Cherbrooks in Canada, researchers have developed a waist mounted remote controlled hydraulic arm. The uniqueness of this arm is its’ ability to carry out gentle tasks as well as having the strength to smash through walls.

The system has 3 degrees of freedom and uses hydraulics and magnetorheological clutches and hydrostatic transmissions. The power system is connected to the user via a teether, reducing the mass required to be carried however this does limit mobility somewhat. The arm weighs 4 kilos and can lift 5 kilos.

Currently the arm is not autonomous as the arm is controlled via a second human using a handheld controller. Uses include working up a ladder where an extra hand is needed but there is no room for a second person, in fruit picking, window washing and handing a tool to a worker.

Robotics are making Film Sets cheaper

One of the biggest costs in film making is the cost of creating authentic looking sets. The small details in the background are important and expensive. The Kuka robot from a UK company called Robocarv is trying to change that.

Working with Expanded Polystyrene, sprayed PV foam and resin, Kuka carves out whatever shape or type of background prop is desired. The company is also able to make shop window displays and props for events.

Paying it Forward

If you have a start-up or know of a start-up that has a product ready for market please let me know. I would be happy to have a look and feature the startup in this newsletter. Also if any startups need introductions please get in touch and I will help where I can.

If you have any questions or comments please email me via my website craigcarlyon.com or comment below.

I would also appreciate it if you could forward this newsletter to anyone that you think might be interested.

Now this is research. If we can get a antimatter drive into a Tesla truck should get to Mars in a day...