This week we discover a new class of materials that are both able to absorb shocks and retain its’ stiffness. We investigate a way to paint wounds in order for them to heal faster and we examine a new self healing lens for self driving cars. Finally we look at something that every parent has always wished for and that every kid has demanded. A way to make vegetable taste better.

A new Class of Materials

Materials are usually either stiff or can absorb vibrations. The two qualities are considered mutually exclusive, until now. A team at the University of Amsterdam have developed a way to create materials that are stiff but that can also absorb vibrations. Also significantly the new materials are lightweight.

The team discovered that if they used materials that buckled such as thin metal sheets and put them together in an interesting way they became great absorbers of vibrations. The materials still preserved a lot of the stiffness of the original materials. The sheets do not have to be very thick to achieve this property so the new material can be kept relatively light.

There are a range of uses for this type of material ranging from the large to very small. Applications potentially exist in aerospace, automobiles and other civil types of machinery in addition to microscopic applications such as microscopes and nano lithography.

Painting Wounds to Heal them Faster

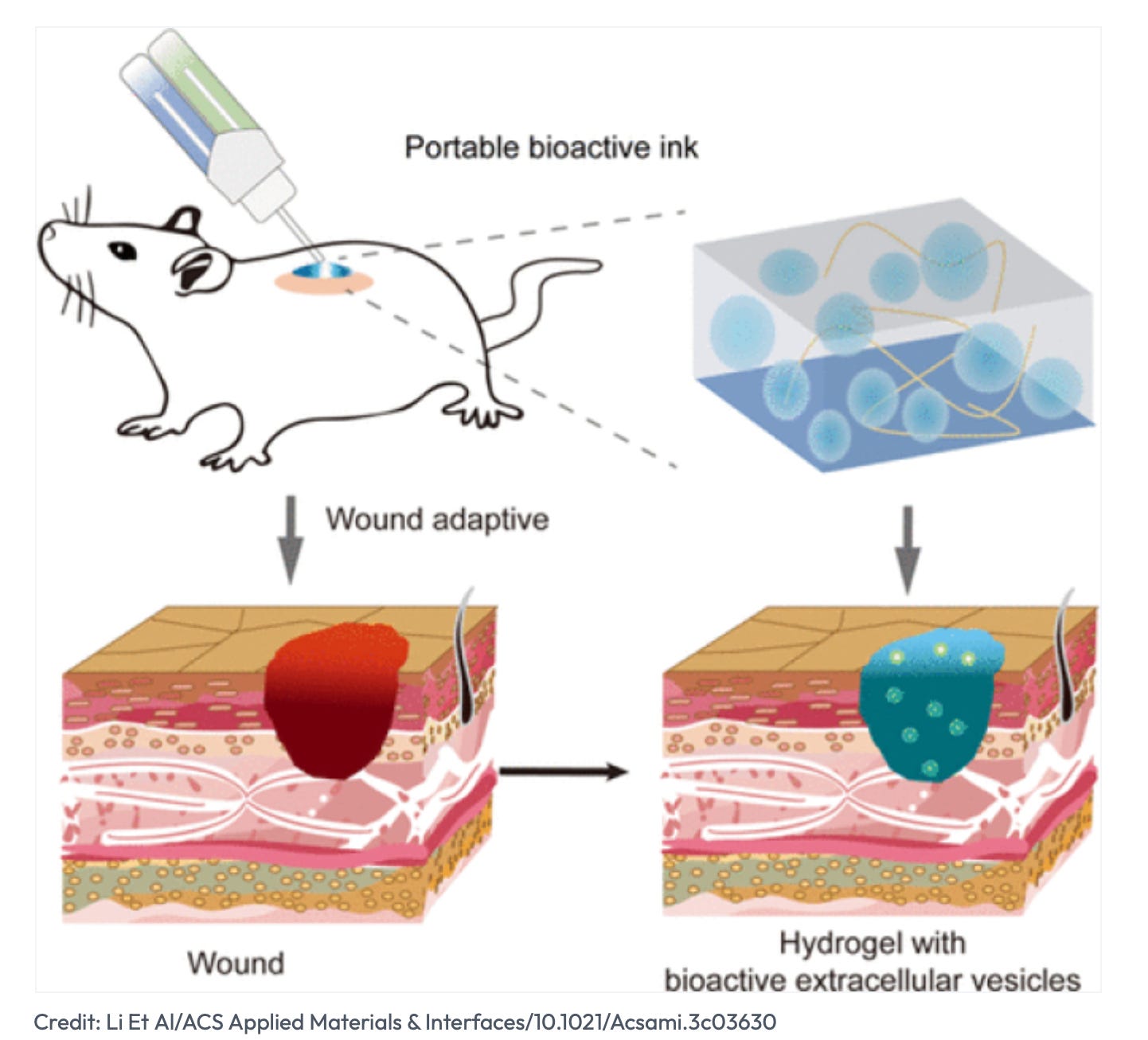

Wounds on the skin are a significant health risk due to the prevalence of infection. We usually use stitches, bandages and antibiotics to help the body repair the damage. New research has shown that by adding white blood cells, which promote wound healing, to current wound healing treatments we can accelerate the natural healing process.

A team from Nanjing University of Posts and Telecommunications, Chinese Academy of Science and the Agency for Science, Technology and Research in Singapore have created a wound healing kit to actively promote the body’s natural ability to heal.

When a wound occurs the body initiates hemostasis to stop bleeding. Blood vessels in the area restrict blood flow. Platelets then activate and aggregate at the wound site to form a blood clot and seal the wound. An inflammatory process begins where white blood cells remove debris and fight infection. Once this is complete a remodeling process takes place to refine and strengthen the healed tissue. Throughout the healing process a range of growth factors, cytokines and other signaling molecules are released to regulate cell behavior, promote tissue repair and moderate inflammation. Nutrition, oxygen supply and a healthy immune system are vital to heal the wound.

White Blood cells (or extracellular vesicles i.e. EVs) can be released by various types of cells involved in wound healing. The team incorporated EVs into a hydrogel based ink that can be painted onto a wound of any shape. The EVs are combined with sodium alginate to keep a moist environment, facilitate healing and promote tissue regeneration. The components are combined at the tip of a 3D printing pen in approximately 3 minutes to create the gel.

The team tested their technology on mice and found that even large wounds were fully healed within 12 days. The product is easy to apply and works on a wide variety of wounds. If the product is suitable for humans it has the potential to cut the recovery time from surgery and accidents significantly.

Self Healing Lens

One of the issues with self driving cars is scratches on the surface of the sensors. Once a lens of a sensor is damaged by scratches, from insects, stones or general wear and tear, the image or optical signal received by the sensor is distorted. This can cause recognition errors and problems with LiDAR systems and other image sensors. It has caused some traffic accidents in testing.

A team at the Korea Research Institute of Chemical Technology and Kyungpook National University have developed a material that heals scratches on the surface of the lenses used in autonomous vehicles. The material can remove scratches within 60 seconds of sunlight being shone and focused onto the surface (e.g. by using a magnifying glass).

The team combined a thiourethane structure (already used in lenses) and a transparent photo thermal dye. This gave a material in which the polymers repeatedly disassemble and recombined under irradiated sunlight. The dye can selectively absorb light of a near-infrared length (850-1050 nanometers) without interfering with the visible light used by optical sensors (350-850nm) or wavelengths used by LiDAR detectors (1550nm).

When the sunlight is absorbed by the dyes the surface temperature of the material rises as the light energy is absorbed. The light energy is being transformed into thermal energy. This increased temperature makes it possible for the scratches to self heal by repeating the dissociation and recombination of the chemical bonds in the material. The process still works after repeated scratches in the same part of the material.

Applications are not limited to autonomous vehicles. Cameras and glasses may also have their useful lifetimes extended by using this technology.

Improving the Taste of Vegetables

Over the years selective breeding of new varieties has improved the taste of some vegetables. For example Brussels Sprouts now taste very different to how they tasted when I was a toddler. Modern plant breeders are now using gene editing technology to replicate this with other vegetables.

In the 1990’s it was discovered that the chemical group called glucosinolates made Brussels Sprouts taste bitter. Plant breeders started growing previously discarded seeds (due to low yields) to try an identify plants with lower levels of these compounds. They then cross bred these low yield but tastier plants with modern higher yielding plants until they found a descendant that grew prolifically and tasted good. The once maligned vegetable is now a tasty side dish (yes I am with most of you, I never give up the dislikes of my youth despite the improvements being made by science).

Most other vegetables have not had the same type of taste improvement as most breeding decisions are made for disease resistance not taste. There is also resistance to genetically modified plants at a consumer level (GMO plants have genes added from different plants). This has led to a reluctance to experiment with breeding. Newer plant breeding techniques have overcome this problem as breeders can now work within the plants’ own genome.

CRISPR and other techniques have made experimentation easier and much cheaper however taste is difficult to target as people have very different tastes. Pairwise, a North Carolina based agricultural company is working on this very problem. They have modified Kale to turn off the enzyme called myrosinase. This enzyme breaks down the glucosinolates and creates bitterness once the leaf is chewed in the mouth. They have created a healthy but less bitter green food. It is now being marketed under the brand Conscious Foods.

The main focus for now is to remove the tastes that most people really don’t like. Creating new tastes is a lot more complex and traditional breeding is still the preferred method. Educational programs trying to get people to eat better have mostly failed. Give people things that taste better and they will eat them and their health will improve.

Paying it Forward

If you have a start-up or know of a start-up that has a product ready for market please let me know. I would be happy to have a look and feature the startup in this newsletter. Also if any startups need introductions please get in touch and I will help where I can.

If you have any questions or comments please comment below.

I would also appreciate it if you could forward this newsletter to anyone that you think might be interested.

Till next week.